The open-source RISC-V architecture is rapidly transforming safety-critical embedded development — from automotive and aerospace to industrial and medical systems. Traditionally, teams in these domains relied on legacy instruction set architectures (ISAs) with long-proven safety certification toolchains.

Today, the growing adoption of RISC-V is powered by three major drivers:

freedom from licensing constraints, modular and extensible ISA design, and mature verification and certification tools — particularly from LDRA.

Why RISC-V Is Gaining Ground

RISC-V’s flexibility and open ecosystem make it ideal for embedded systems that demand efficiency, low power consumption, and design freedom.

But in safety-critical markets, the true turning point came only when functional-safety toolchains reached full maturity — ensuring compliance with ISO 26262, DO-178C, EN 50128, and similar standards.

That’s where LDRA has been instrumental: its safety-certified analysis and verification suite enables developers to integrate RISC-V seamlessly into certified development environments.

Verification, Traceability & Certification — Powered by LDRA

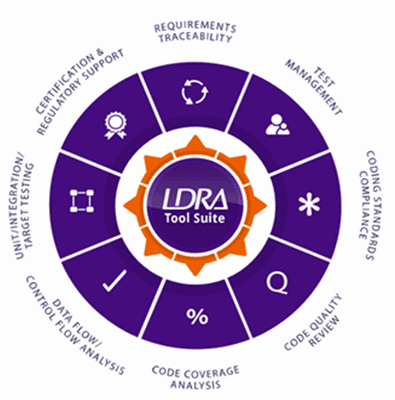

Modern RISC-V projects can now rely on LDRA’s verification ecosystem, supporting:

- Static and dynamic code analysis for deep visibility into RISC-V software behavior

- On-target testing and coverage metrics (including MC/DC)

- Worst-case execution time (WCET) measurement

- Bidirectional traceability from requirements to source and test artifacts

This maturity level means developers can confidently treat RISC-V as a first-class ISA for high-integrity embedded systems.

Key Safety-Critical Use Cases

- Automotive & ADAS: RISC-V CPUs are being qualified to ASIL-B/D, supported by LDRA’s verification tools that streamline ISO 26262 compliance.

- Aerospace & Railway: The open hardware model enables bespoke implementations, while LDRA provides DO-178C and EN 50128 certification support.

- Industrial & Medical: Long lifecycle, deterministic performance, and cost efficiency benefit from RISC-V’s flexibility and LDRA’s proven safety infrastructure.

What It Means for Embedded Engineers

For development teams working with ITEC LTD and our safety-critical partners, the message is clear:

- Adopt RISC-V where you need safety, scalability, and design freedom.

- Integrate LDRA tools early to ensure compliance, traceability, and certification readiness.

- Leverage open architectures to innovate faster while maintaining functional safety integrity.

Conclusion

RISC-V is no longer experimental — it’s becoming the preferred ISA for safety-critical systems.

With LDRA’s toolchain providing the essential foundation for verification, testing, and certification, embedded teams can confidently transition to RISC-V while meeting the world’s toughest safety standards.